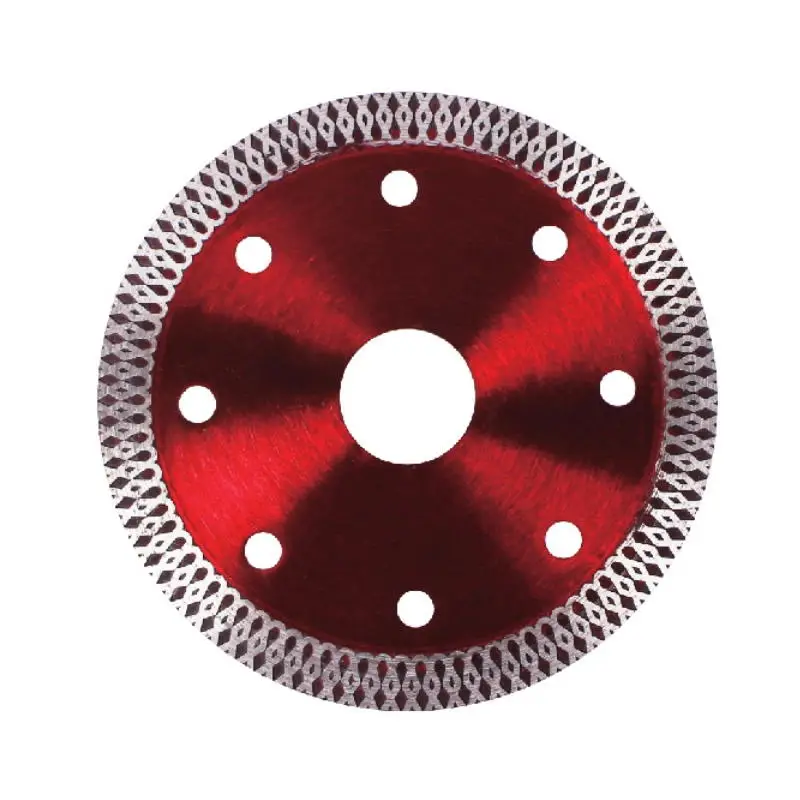

Hey kids! Another addition to the home that I undertook by myself in our previous kitchen was sanding, preparing and polishing a concrete floor for tulsa stained concrete with steel cutting blade. If you did not, hold on to your britches! And today we will tell you all about a sharp steel cutting blade. This tool is pretty fun as well if you want to reduce or cut the metal easily. We will also explain blade selection buying advice to ensure you cut clean without fear and the mess. So, without further ado …angles away.

A sharp steel cutting blade is an extremely deadly tool when it would come seamlessly stunning with 3 mm wide metallic. Like a metal superhero! But remember: A dull blade is dangerous. A dull blade just means that it is no longer sharp. The effect this will have is that it might be more difficult to cut through metal, and you may need too use a lot more force. When your blade is dull many things can occur, slip and cause an accidental cut of yourself or even worse some other person in the vicinity. This is why your blade should stay sharp!