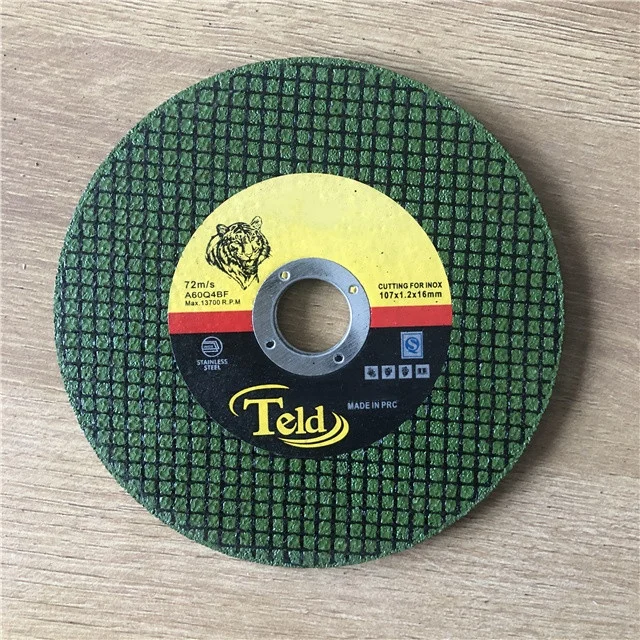

Често ли си задавате въпроса как всички метални предмети получават толкова блестящ и същевременно гладък повърхност? Е, шлифовачната диска е инструмент, който точно това ви позволява! Шлифовачната диска е кръгъл диск, който се монтира на различни електроинструменти и служи като абразивен материал, който помага при формирането или преобразуването на метални повърхности. Този инструмент е отличен аксесоар за всеки, който работи с метал и иска да подобри неговия общ вид.

Фактът е, че не всички шлифовачни дискове са еднакви (1). За да стигнете до най-добрия метален повърхност, е важно да използвате специална шлифовачна диска, предназначена за метал. Основната причина е, че тези дискове обикновено съдържат материали: например, компоненти като алуминиев оксид или диамант. Абразивните материали лесно премахват изгледанията, вмляни и петна от повърхността на металите, разкривайки ярка нова видимост.