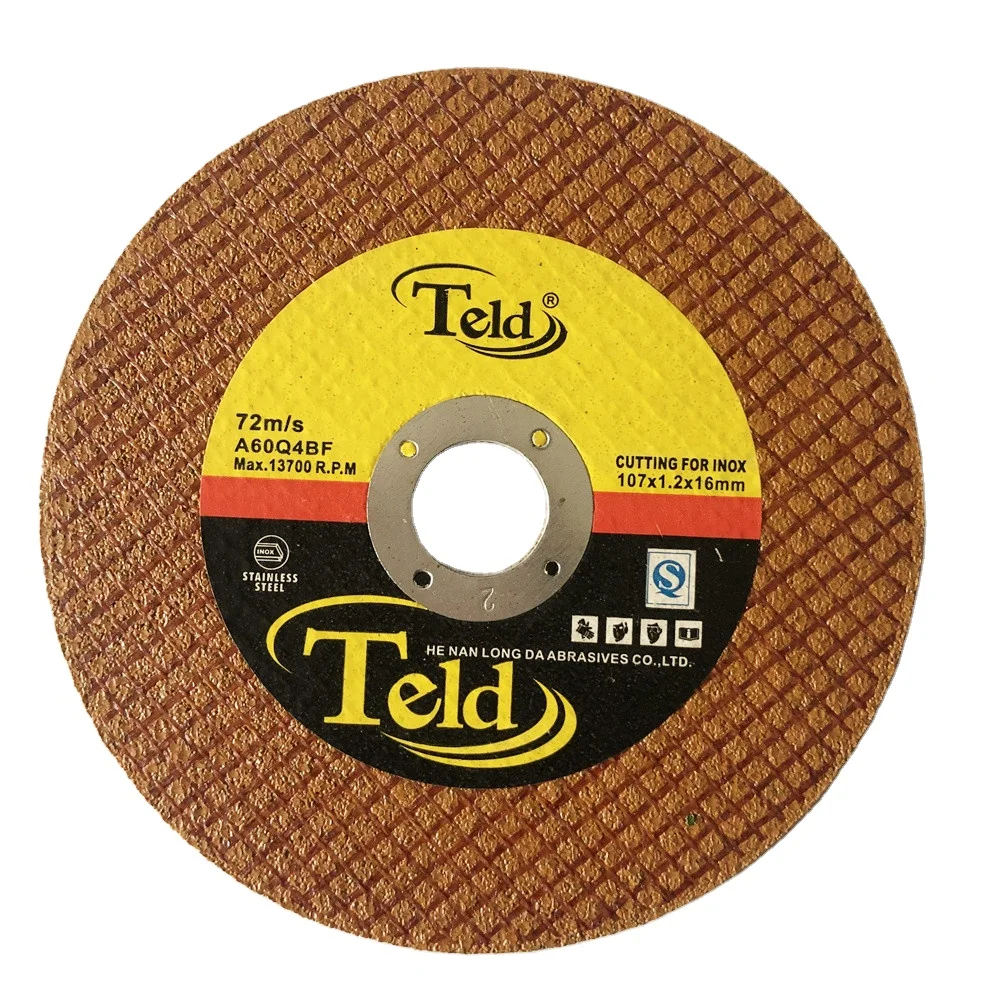

Дисковидната плоча, от друга страна, е много полезна за обработка на повърхността, за да стане гладка и с прекрасен вид. Всъщност можем да я използваме като кръгъл диск за множество цели. Например метален дисковиден диск и тип 29 (при ъгълен материал се премахва повече от плосък) е най-добрият случай за неръдеща стомана. В тази статия ще научите защо бихте могли да използвате такъв тип плоча и как тя ви помага в задачите.

Неръжавеща: Метал, който не ржавее. След думата неръжавеща има думата оцел в края, и тя е неръжавеща благодарение на съпротивността си към образуването на ржа, което я прави пригодна за различни цели, които използваме, като кухненски апарати, раковини дори инструменти. Тогава може ли неръжавещата оцел да получи гладкият завършване? Е, тук идва неръжавещата оцелова плоча, за да те помогне! Освен това тя прави полирването на неръжавеща оцел МНОГО по-лесно и всички обичат добър зъркален завършване.