Як абрыўныя калёса ўплываяць на рынок металаў

Дужа даўно, перш чым былі ўведзены дыскі для разрэзу, праца з металам была трудахлебнай і часапазлікай праект. У агульныму, інструменты, якія карыстались раней, былі абмежаваныя для певнага рэвела самадзейных чалавек, якія проста не мелі іншага выбару, калі не традыцыянныя піля і абладнанне для навет прастых разрэзаў. Але ўводзенне дыскіў для разрэзу перафармавала працу з металам, як мы яе ведаем. З таго дня, новае параджэнне металургаў стварыла складаныя дызайны і праводзіла правальныя разрэзы ў кусках метала.

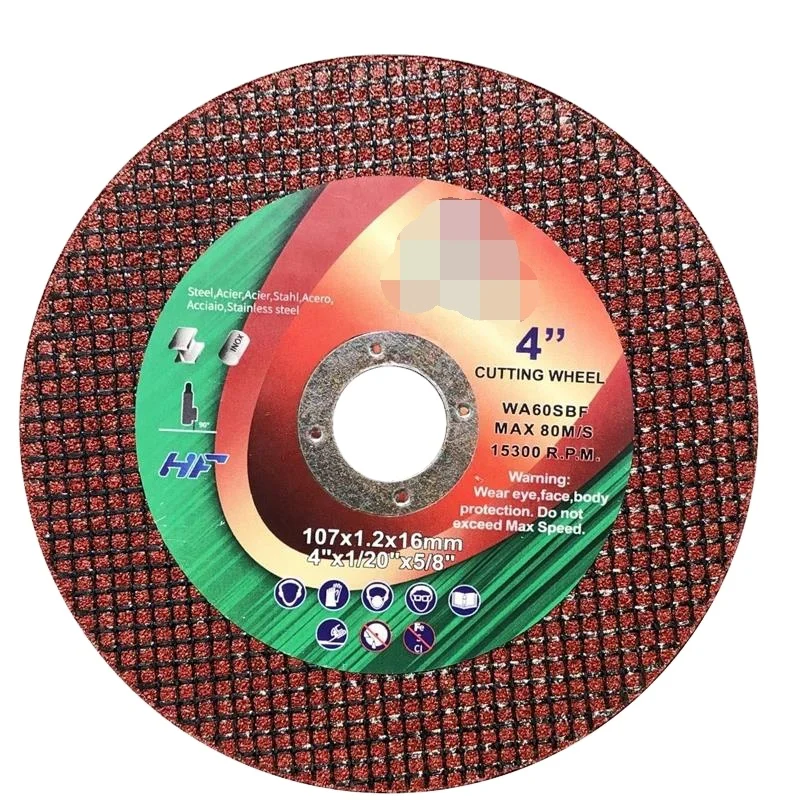

Паўнаважны гід па выбары правільнага дыску для разрэзу

Для таго каб пачаць сваё паездніна ўспеху ў металавай роботе, неабходзя выбраць фармавальны кола, якое ідзе дакладна ў кожны праект. Перш чым выбраць фармавальнае кола, ацэньце тып метала матэрыяла, які трэба нарэзаць, а таксама яго цуску і памер нарэза. Коли вы маеце ў руках патрэбнае фармавальнае кола, закрепіце яго ў шліфавальнай машине і не забудзіце надяць абарончую эkipiруванне. Пасля гэтага, пачніце працаваць над секцыямі ваших праектаў, нарэзаваючы прымацільна або грацыянныя крывыні. Працуйце крок за крокам і паўольна, каб атрымаць дакладныя вынікі.

Калі вы палюбляеце працаваць з металам, а таксама калі вам меней, чым бяспечнае ўзростовая межа, для вас гэтыя фармавальныя кола могуць стануць пераўтварчай сілай. Пасля таго, як вы зможаце ўладаць хуткасцю правядзення праваугольнага шліфавання, злучыце тэхнікі з дыскам для нарэза, докуль вашы праекты не дасягнут новага размера і якасці ў тэрмінах дакладнасці ці кreatыўнасці. Так што, добрыя адмыслы ў метале!